Level measurement and point level detection in rock crushers

Category: Building materials

Specifications

Details

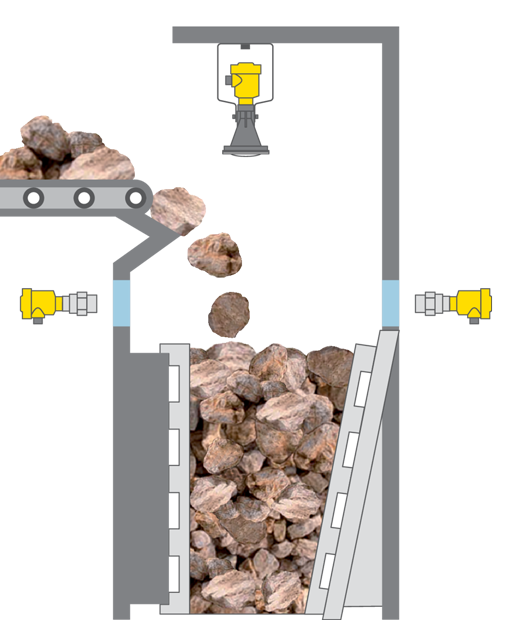

Crusher

Level measurement and point level detection in rock crushers

Process data

Measuring task

Level measurement and point level detection

Measuring point

Crusher

Measuring range up to

5 m

Medium

Stones

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Strong noise and dust generation, extreme abrasion

Application

The large boulders are extracted from the solid bedrock with blasting. This very first stage in the process is needed to enable these very large rocks to be crushed by smaller, secondary jaw and roller crushers, which create the smaller sizes for screening to produce the basic building materials like gravel, grit or sand. To enable efficient, continuous operation and keep wear on the crusher as low as possible, level measurement and point level detection are required.

Your benefit

Reliable

Reliable measurement ensured even in noisy environments

Cost effective

Uninterrupted operation thanks to optimal process feed

User friendly

Simple installation and setup

Recommended products

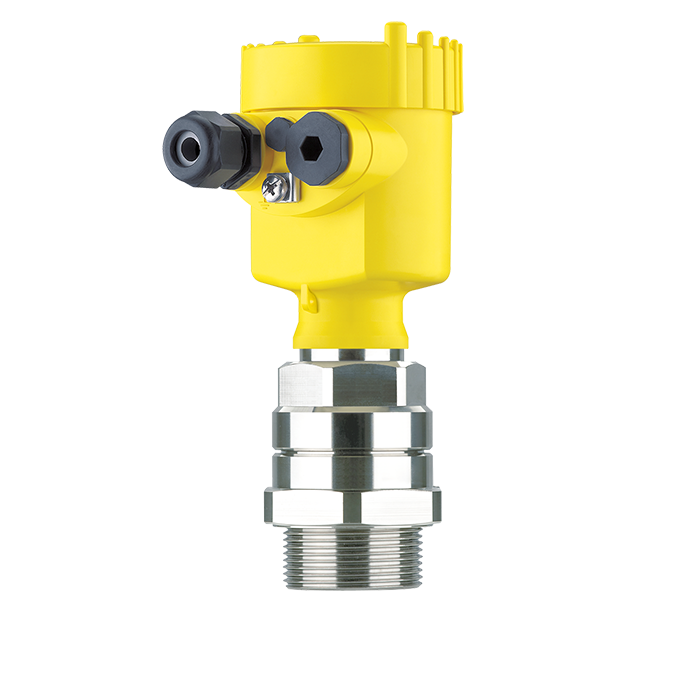

VEGAPULS 69

Non-contact level measurement with radar in rock crushers

- Reliable measurement and control, independent of extreme dust generation and weather conditions

- Maximum operational reliability through noise insensitivity

- Maintenance-free non-contact measuring method

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

VEGAMIP 61

Microwave barrier for point level detection in rock crushers

- Maintenance-free non-contact measuring method

- High measurement certainty despite dirt and buildup

- Even external measurement via solid plastic or ceramic window

Measuring range - Distance

100 m

Process temperature

-40 ... 80 °C

Process pressure

-1 ... 4 bar

View more about Level measurement and point level detection in rock crushers on main site