Level measurement and point level detection in the lime milk storage tank

Category: Energy

Specifications

Details

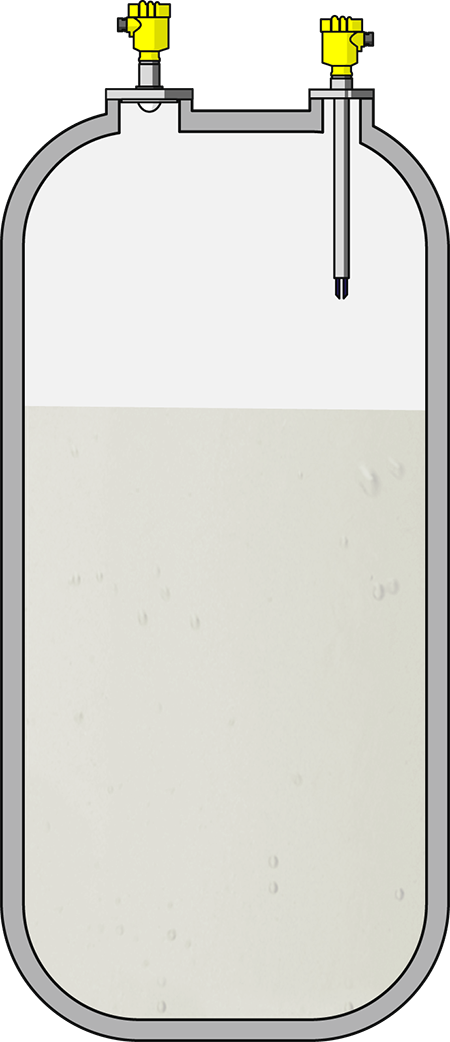

Lime milk storage tank

Level measurement and point level detection in the lime milk storage tank

|

|

Process data

Measuring task

Level measurement and point level detection

Measuring point

Lime milk storage tank

Measuring range up to

8 m

Medium

Lime milk

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Abrasive and aggressive medium

Application

The sulphur in the flue gas is chemically bound by injecting lime milk into the scrubbing tower. To ensure that there is always enough lime milk available for the scrubbing tower, sensors are required to regulate the level and reliably prevent an overfilling of the tank.

Your benefit

Reliable

Reliable level measurement and overfill protection

Cost effective

High chemical resistance

User friendly

Maintenance-free, reliable operation of the system

Recommended Products

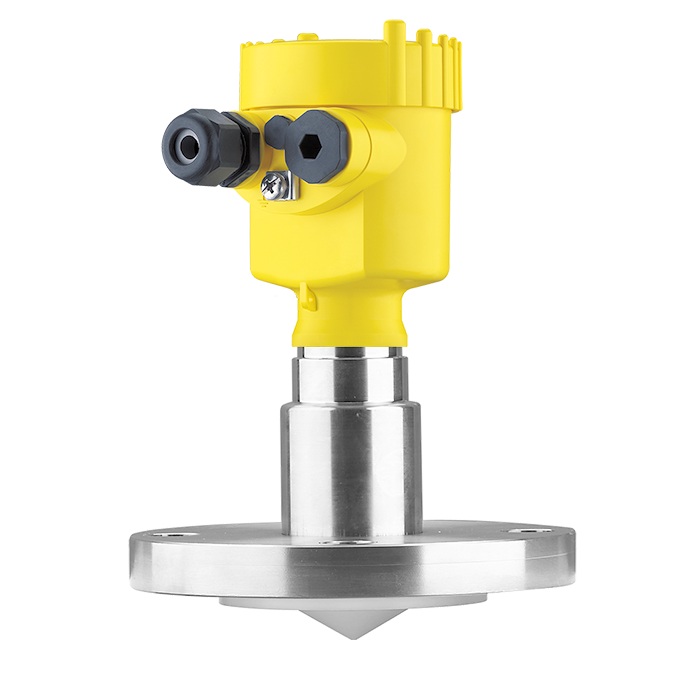

VEGAPULS 63

For measuring the level and ensuring the supply of lime milk

- No buildup on sensor due to flat antenna design

- High plant availability thanks to wear and maintenance-free measuring instrument

- Unaffected by pressure, temperature, gas and steam

- Approvals according to Ex, WHG and SIL2

Measuring range - Distance

35 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 16 bar

VEGASWING 63

The vibrating level switch protects against overfilling and complete emptying of the lime milk tank

- Product-independent switching point ensures millimetre-exact detection of the limit level

- Minimal costs for maintenance and servicing

- Available in different materials, includes Ex, WHG and SIL2 approvals

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

View more about Level measurement and point level detection in the lime milk storage tank on main site