Level measurement in an aluminium powder suspension reactor

Category: Mining and metal processing

Specifications

Details

Reactor

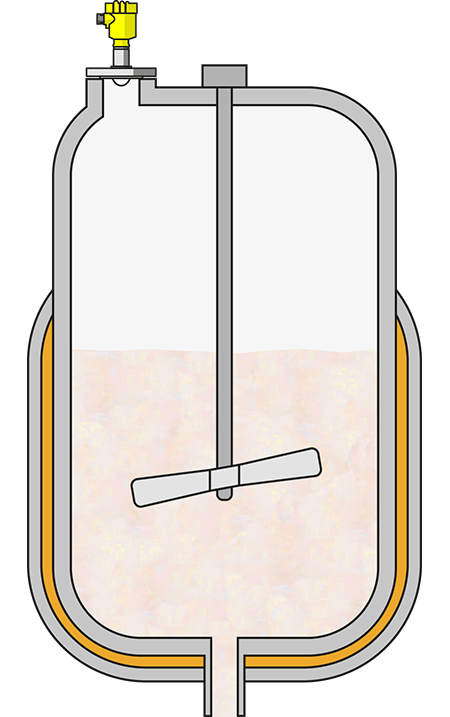

Level measurement in an aluminium powder suspension reactor

Process data

Measuring task

Level measurement

Measuring point

Reactor

Measuring range up to

1.2 m

Medium

Aluminium powder suspension

Process temperature

0 … +130 °C

Process pressure

0 … +0.3 bar

Special challenges

Low dielectric constant, confined spaces, strong turbulence on the product surface, condensation

Application

Aluminium powder suspension is an intermediate for titanium sponge production. In the reactor, vanadium oxide trichloride is removed from the aluminium powder suspension. When the aluminium powder suspension is fed into the reactor, strong turbulence arises on the product surface. To optimize the process, the level in the reactor must be accurately measured and monitored.

Your benefit

Reliable

Reliable measurement despite small dielectric constants

Cost effective

Reliable measurement of the entire reactor volume

User friendly

Simple mounting and setup

Recommended products

VEGAPULS 64

Non-contact level measurement with radar in the reactor

- Good signal focussing allows use in tight spaces

- Unaffected by condensate and deposits on the antenna

- Strong focussing allows reliable measurement at close range and at the bottom of the tank as well as in media with low dielectric constant

- Maintenance-free through non-contact measurement

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

View more about Level measurement in an aluminium powder suspension reactor on main site