Details

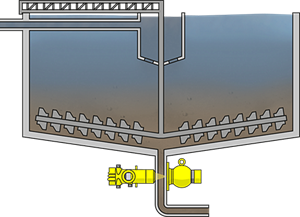

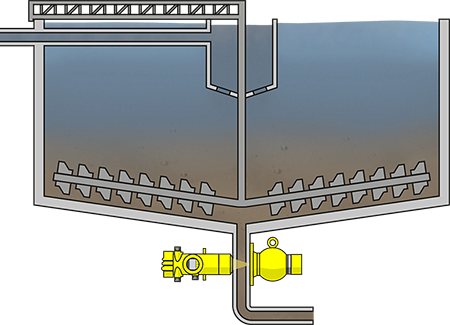

Ore thickener

Density measurement in the ore thickener

Process data

Measuring task

Density measurement

Measuring point

Tank

Measuring range up to

1000 – 1300 kg/m³

Medium

Different ores

Process temperature

+15 … +25 °C

Process pressure

0 … 0 bar

Special challenges

Abrasive medium

Application

Extracted minerals are fed to the thickener as a slurry via a trough. The solids are settled out into the bottom of the tank, in a process accelerated through the addition of flocculants. Precise density measurement of the slurry underflow is necessary for effective control of the ore thickener.

Your benefit

Reliable

Reliable determination of solid content under all operating conditions

Cost effective

Cost savings through optimised flocculent dosage

User friendly

Simple mounting and setup

Recommended products

MINITRAC 31

Radiometric density measurement in the ore thickener

- Simple retrofitting during ongoing production processes

- High plant availability using non-contact measurement

- Exact measuring results, independent of process conditions

Measuring range - Distance

-

Process temperature

-40 ... 60 °C

Process pressure

-

VEGASOURCE 31

Container for radioactive source capsules

- Trustworthy shielding allows use without control areas

- Minimal space requirements and simple mounting

- Operational safety through pneumatic ON/OFF switching

Ambient temperature

-20 ... 80 °C

View more about ensity measurement in the ore thickener on main site