Density-compensated level measurement in flotation cells

Category: Mining and metal processing

Specifications

Details

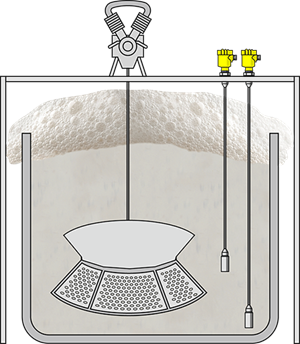

Foam flotation cell

Density-compensated level measurement in flotation cells

Process data

Measuring task

Density and level measurement

Measuring point

Tank

Measuring range up to

1 m

Medium

Suspended solids in liquid

Process temperature

+25 ... +35 °C

Process pressure

+80 ... +200 mbar

Special challenges

Density changes, buildup, abrasion, turbulent medium surface

Application

To work efficiently, flotation cells depend on continuous froth formation. If the froth layer is too thin, it cannot transport the sufficient amount of dispersed or suspended particles to the surface. On the other hand, froth that is too thick indicates that the reaction time of the chemicals is too long. This has the consequence that too little of the medium gets processed. A density-compensated level measurement is the reliable solution in this process: this ensures that the density of the liquid remains constant and optimizes the process yields over a long period.

Your benefit

Reliable

Reliable measurement without capillaries, impulse lines or mechanical parts

Cost effective

High process efficiency thanks to optimum foam level

User friendly

Low-maintenance, wear-free operation with ceramic measuring cells

Recommended products

VEGABAR 86

Electronic differential pressure measurement for density-compensated level measurement

- Reliable measurement for maximization of flotation efficiency

- Abrasion resistant thanks to CERTEC® ceramic measuring cell

- Measures density, level and temperature simultaneously

Measuring range - Pressure

0 ... 25 bar

Process temperature

-20 ... 100 °C

Process pressure

0 ... 25 bar

View more about Density-compensated level measurement in flotation cells on main site