Level measurement and point level detection of liquid raw materials in storage tanks

Category: Oil and gas offshore

Specifications

Details

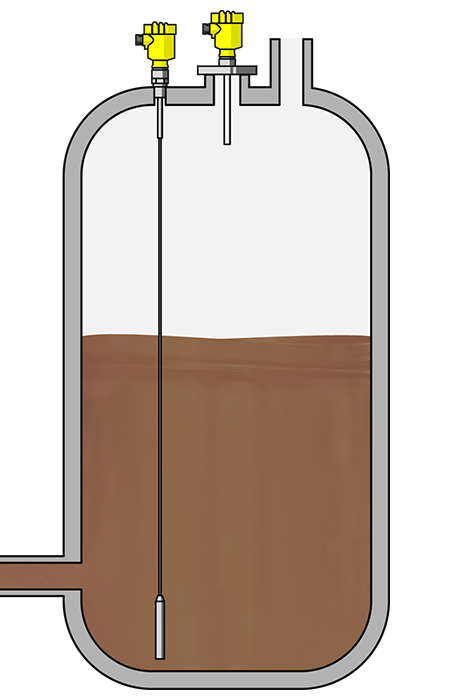

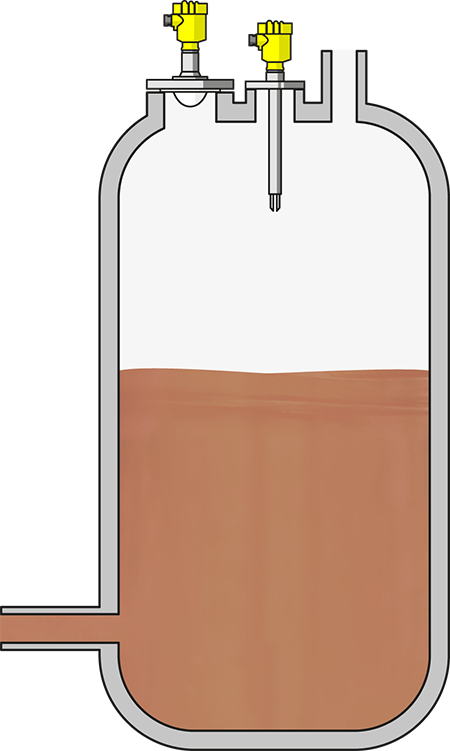

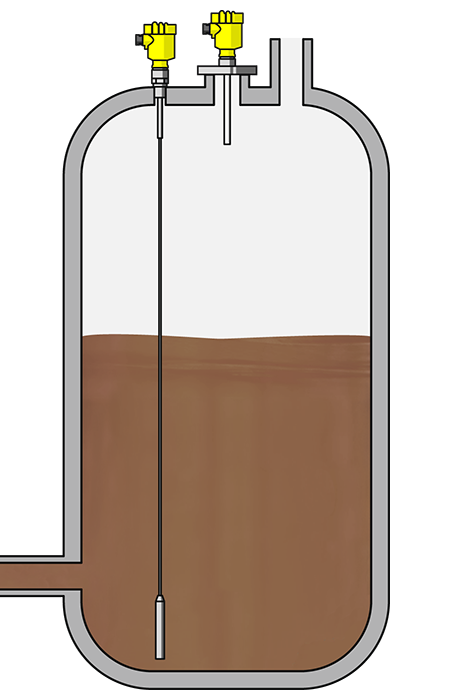

Storage tank for liquid raw materials

Level measurement and point level detection of liquid raw materials in storage tanks

|

|

Process data

Measuring task

Level measurement and point level detection

Measuring point

Vessel

Measuring range up to

15 m

Medium

Oils and alkaline solutions

Process temperature

0 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Buildup, foam

Application

Oils and alkaline solutions are among the liquid raw materials for the mud mixtures. These additives are stored on the drilling platform in special storage tanks. To ensure the continuous production of drilling mud, the level of raw materials in the storage tanks must be exactly monitored.

Your benefit

Reliable

Reliable measurement, independent of product characteristics

Cost effective

Maintenance-free operation

User friendly

Simple setup and commissioning

Recommended products

VEGAFLEX 81

Level measurement with guided radar in storage tanks for liquid raw materials

- Simple project planning enabled by shortenable rod and cable probes

- Long service life thanks to highly resistant materials

- Non-sensitive to buildup and foam

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

VEGASWING 63

Level switch for detecting the maximum level in the storage tank for liquid raw materials

- Reliable measurement, independent of mud characteristics

- Robust construction ensures a long service life

- Simple setup without adjustment

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

View more about Level measurement and point level detection of liquid raw materials in storage tanks on main site