Details

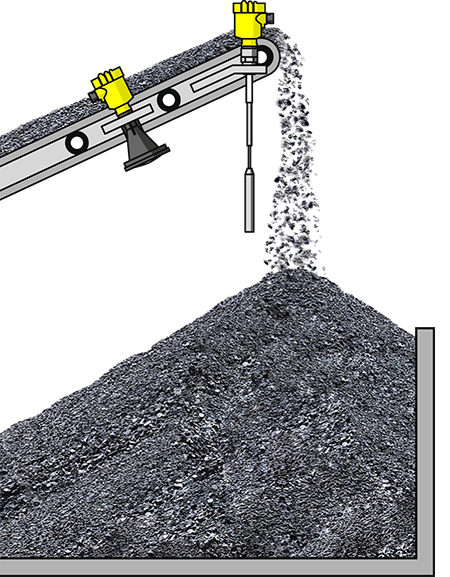

Coke stacker

Stockpile monitoring

Process data

Measuring task

Level measurement and point level detection

Measuring point

Open mound

Measuring range up to

30 m

Medium

Coke

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Weather, coke dust

Application

After the coke is extracted from the drums it is stored in silos or stockpiles. Reliable level measurement is an absolute must for automating the stockpiling process and ensuring optimal levels.

Your benefit

Reliable

Consistent measuring results in any weather

Cost effective

Maintenance-free operation

User friendly

Simple installation on existing infrastructure

Recommended products

VEGAPULS 69

Radar sensor for level measurement in the coke stacker

- Non-contact, maintenance-free measurement

- High measurement certainty despite intense dust and noise generation

- Absolute operational reliability, even in rain and snow

- Simple mounting and setup

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

VEGACAP 65

Capacitive cable probe for level detection in the coke stacker

- Shortenable probes enable high flexibility

- Long service life and low maintenance requirements through robust design

- Reliable switching point ensured through large sensing weight

Process temperature

-50 ... 200 °C

Process pressure

-1 ... 64 bar

Version

Cable ø 6 mm with screening tube without weight

Cable ø 6 mm with screening tube and gravity weight

Cable ø 6 mm with gravity weight

Cable ø 8 mm with abrasion protection without weight

Cable ø 8 mm with abrasion protection and gravity weight

Cable ø 8 mm with gravity weight

PA cable ø 12 mm with screening tube and gravity weight

View more about Stockpile monitoring on main site