Level measurement and point level detection in condensate storage tanks

Category: Refining and petrochemical

Specifications

Details

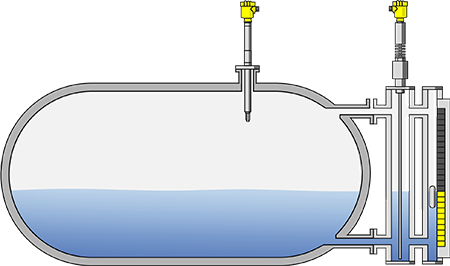

Condensate storage tanks

Level measurement and point level detection in condensate storage tanks

Process data

Measuring task

Level measurement and point level detection

Measuring point

Horizontal bullet

Measuring range up to

3 m

Medium

Water

Process temperature

+120 … +230 °C

Process pressure

+1 … +10 bar

Special challenges

High temperature, steam, condensate

Application

Throughout the different process units, there are storage vessels that collect clean, reusable condensate. This condensate accumulates from the steam system that is used to heat the various hydrocarbon processes. The condensate tanks routinely have extremely high process temperatures, so a level measurement and point level detection are necessary that can withstand this environment.

Your benefit

Reliable

Safe measurement unaffected by high temperature and steam

Cost effective

Maintenance-free through optimal redundancy arrangement

User friendly

Simple setup and installation

Recommended products

VEGAFLEX 86

Level measurement with guided wave radar in condensate storage tanks

- Guided wave radar and magnetic level indicator provide redundancy

- Reliable measurement even under critical process conditions

- Continuous reporting increases operational efficiency

Measuring range - Distance

75 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 400 bar

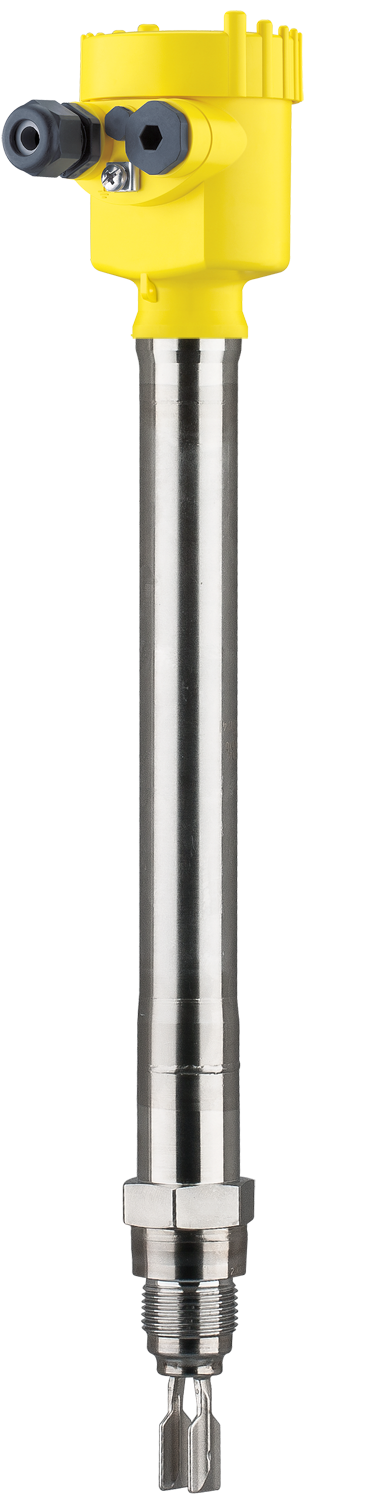

VEGASWING 66

Vibrating level switch for level detection in condensate storage tanks

- Easy retrofit allows use of existing connections without modification

- Resistance to high temperature and steam environments eliminates false switching

- Maintenance-free operation increases the plant efficiency

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

Version

Compact version

with gas-tight leadthrough

with tube extension

View more about Level measurement and point level detection in condensate storage tanks on main site