Level measurement and point level detection of finished product tanks

Category: Refining and petrochemical

Specifications

Details

Finished product tanks

Level measurement and point level detection of finished product tanks

Process data

Measuring task

Level measurement and point level detection

Measuring point

Tank

Measuring range up to

15 m

Medium

Light or heavy hydrocarbon

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Varying hydrocarbon products, possible condensation

Application

Reliable level measurement of crude and bulk liquids storage tanks in a refinery is necessary for inventory management and overspill protection. Multiple measurement devices can fit into a single process fitting.

Your benefit

Reliable

Redundant measurement ensures a high degree of safety

Cost effective

Self-monitoring reduces maintenance costs

User friendly

Easy installation and setup

Recommended products

VEGASWING 63

Vibrating level switch for overfill protection in finished product tanks

- High level switch provides redundancy

- Maximum flexibility through switching point adaptable to the application

- By simply pushing a button, you can meet the requirements of WHG and SIL of the periodic test

- Unaffected by media properties ensures reliable measurement

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

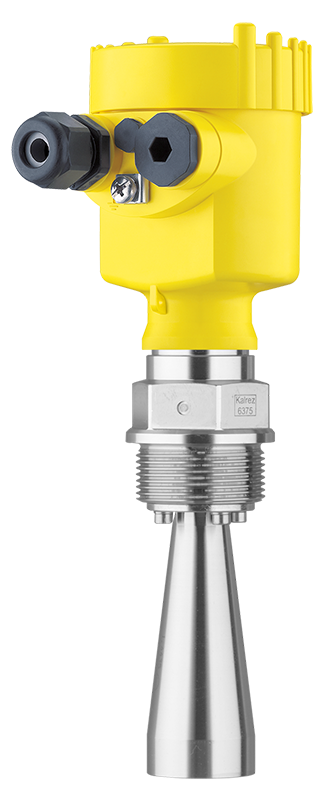

VEGAPULS 62

Level measurement with radar in finished product tanks

- Simple retrofit capability utilizes existing process fittings

- Exact measuring results independent of temperature, gas or steam

- Use of optional PLV (Positive Level Verification) system fulfils API 2350 requirements

Measuring range - Distance

35 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

View more about Level measurement and point level detection of finished product tanks on main site