Details

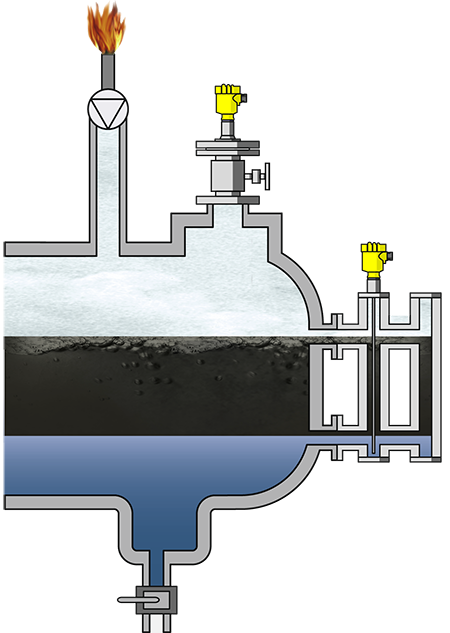

Flare knockout drum

Level measurement in the flare knockout drum

Process data

Measuring task

Level measurement

Measuring point

Bullet

Measuring range up to

3 m

Medium

Hydrocarbon liquid and vapours

Process temperature

+60 … 120 °C

Process pressure

+1 … +12 bar

Special challenges

Condensate, steam

Application

The flare knockout drum requires continuous, accurate level monitoring to keep liquids from reaching the flare and creating a potential fire hazard. In order to ensure safety of process by performing this critical measurement, the total process level over the span of the drum needs to be tracked and continuously reported to the operator for proper control. For measurement in the sump of the flare knockout drum, the sensor provides exact position of interface.

Your benefit

Reliable

Tracks total process level and interface level

Cost effective

Reduced maintenance costs due to no mechanical moving parts

User friendly

Easily fit within mounting constraints

Recommended products

VEGAPULS 64

Radar sensor for continuous level measurement over the span of the knockout drum

- Continuous, quick and exact measurement enable an excellent process control

- Ball valve provides the ability to remove the device without emptying the sphere

- Very good signal focussing ensures accurate measurement even through a ball valve

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

VEGAFLEX 81

Guided wave radar sensor with bridle chamber for interface measurement

- Immune to mechanical failure due to non-moving parts

- Low maintenance requirements reduce downtime and operating cost

- Bridle can be easily isolated to allow easy service without interrupting the process

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

View more about Level measurement in the flare knockout drum on main site