Level measurement and point level detection in the oil skim tank

Category: Refining and petrochemical

Specifications

Details

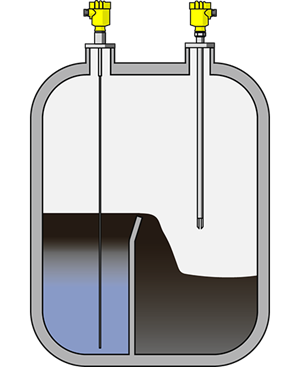

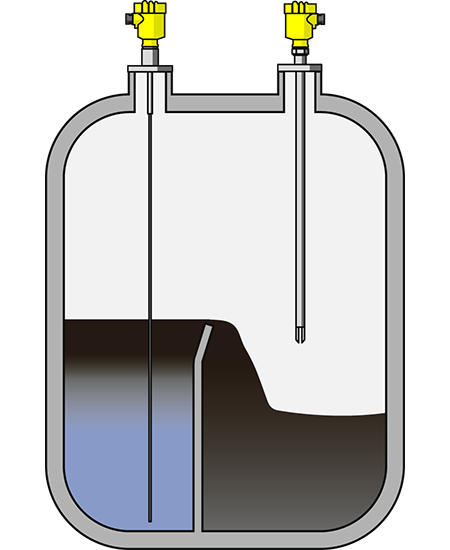

Oil skim tank

Level measurement and point level detection in the oil skim tank

Process data

Measuring task

Level measurement and point level detection

Measuring point

Tank

Measuring range up to

3 m

Medium

Various hydrocarbons and water

Process temperature

+25 … +65 °C

Process pressure

+1 … +7 bar

Special challenges

Buildup, condensate

Application

Accurate measurement in oil skim and separation tanks is critical to product quality because there is complete separation of oil and gas possible. For liquid-liquid interface monitoring an accurate measurement helps control the quality of the separator’s output and thus helps to extend equipment life in downstream units by avoiding any potentially expensive impurity problems.

Your benefit

Reliable

Safe measurement unaffected by changing medium properties

Cost effective

Reliable control of the interface ensures effective operation

User friendly

Simple and easy setup

Recommended products

VEGASWING 63

Vibrating level switch as overfill protection in the oil skim tank

- Non-moving parts reduce maintenance needs

- Unaffected by process conditions

- Product independent switching point

- Simple setup without adjustment

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

VEGAFLEX 81

Guided wave radar for interface control in the oil skim tank

- Non-moving parts eliminate maintenance needs

- Almost independent of buildup and condensate

- Immunity to the crude supply density changes offers reliable continuous level control

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

View more about Level measurement and point level detection in the oil skim tank on main site