Level measurement and point level detection in sulphur pits

Category: Refining and petrochemical

Specifications

Details

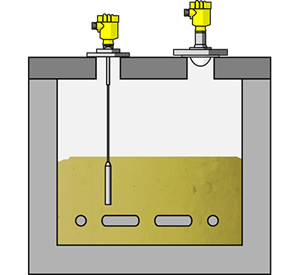

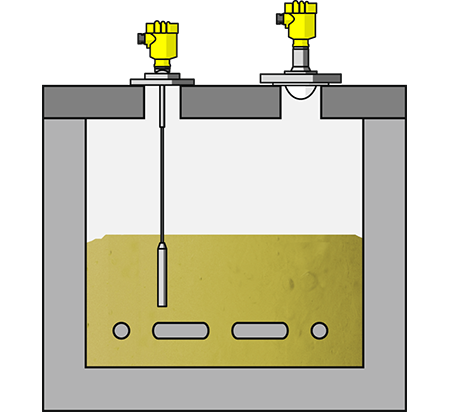

Sulphur pit

Level measurement and point level detection in sulphur pits

Process data

Measuring task

Level measurement and point level detection

Measuring point

Concrete pit

Measuring range up to

30 m

Medium

Elemental sulphur

Process temperature

+150 … +200 °C

Process pressure

+1 … +1.5 bar

Special challenges

High temperature, buildup, corrosive medium

Application

The liquid sulphur, which comes directly from the sulphur recovery plant, is stored in underground concrete pits. High temperatures are required to maintain the sulphur in its liquid form. The harsh, corrosive process and environmental conditions in sulphur pits require both dependable level measurement and point level detection.

Your benefit

Reliable

Unaffected by buildup or condensate

Cost effective

Maintenance-free operation

User friendly

Easy setup and installation

Recommended products

VEGAPULS 64

Non-contact level measurement with radar in sulphur pits

- Maintenance-free operation through non-contact measuring principle

- Wetted parts are extremely corrosion resistant

- Reliable measurement independent of vapour, buildup and condensation

- Very good focusing allows reliable operation even in confined spaces

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

VEGAFLEX 81

Continuous level measurement with guided wave radar in sulphur pits

- Reliable measured values even with foam

- Non-sensitive to vapour, buildup and condensation

- No moving parts and thus no need for maintenance

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

View more about Level measurement and point level detection in sulphur pits on main site