Details

Sumps

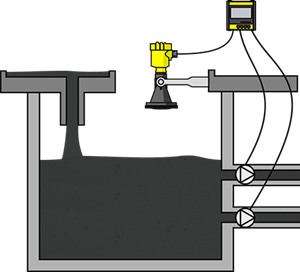

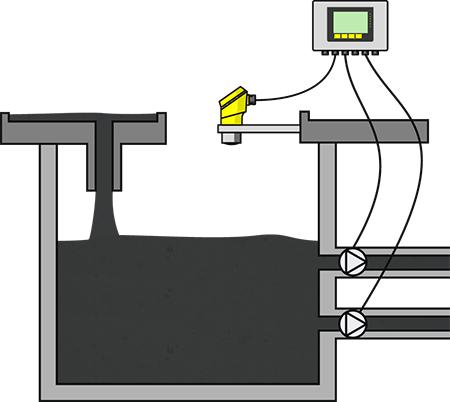

Sump level control

Process data

Measuring task

Level measurement

Measuring point

Sump

Measuring range up to

3 m

Medium

Water and hydrocarbons

Process temperature

-40 … +45 °C

Process pressure

+1 … +3 bar

Special challenges

Foam, buildup

Application

The level in the sumps around a refinery must be reliably monitored to prevent overfilling and subsequent pollution, or pump overload. Balanced pump utilization is possible thanks to a pump control rotation system integrated into the signal conditioning instrument.

Your benefit

Reliable

Measurement optimizes pump usage via pump control functions

Cost effective

Pump control ensures energy conservation and long pump service life

User friendly

Easy setup and installation

Recommended products

VEGAPULS 64

Radar sensor for continuous level measurement in sumps

- Very good signal focusing ensures accurate measurement, even in confined spaces

- Reliable measurement, unaffected by condensation on the antenna

- Maintenance-free operation thanks to non-contact measuring principle

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

VEGAMET 391

Signal conditioning instrument for continuous lead-lag changeover control of pumps

- Integrated pump control function ensures longer pump service life

- Simple setup and installation reduces installation costs

- Six relay outputs, one scalable current output

Protection rating

IP 20/IP 65

Input

1 x 4 … 20 mA/HART sensor input

with transmitter power supply

Output

1 x 0/4 … 20 mA current output

up to 6 x operating relay

1 x fail safe relay

1 x Ethernet or 1 x RS232

View more about Sump level control on main site