Point level detection for bilge and leakage monitoring

Category: Ship and yacht building

Specifications

Details

Bilges

Point level detection for bilge and leakage monitoring

Process data

Measuring task

Point level detection

Measuring point

Bilge, oil pan

Measuring range up to

Switching point

Medium

Oil/oil-water mixture

Process temperature

+10 … +75 °C

Process pressure

0 … 0 bar

Special challenges

Inaccessible measuring points, ship approvals

Application

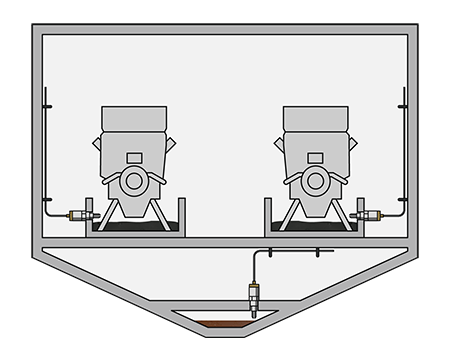

Every ship has ‘bilges’ – this is space at the lowest point of the vessel between the floor of the engine room and the bottom of the ship. A water/oil mixture collects in this bilge area, where the mixture is pumped out and recovered and separated into water and oil by an on-board skimmer and demulsifying unit. The bilge de-oiling equipment is normally controlled by level switches. The oil sumps of the main engine and any auxiliary systems must also be monitored continuously for safety and environmental reasons.

Your benefit

Reliable

Maximum safety for humans and the environment

Cost effective

Simple installation

User friendly

Maintenance-free and reliable operation

Recommended products

VEGASWING 51

Vibrating level switch for point level detection in bilge and oil pan

- Compact design allows installation in almost any position

- Maintenance-free operation, as the vibrating level switch has no mechanical moving parts

- Foam, bubble formation and viscosity do not influence switching accuracy

Measuring range - Distance

-

Process temperature

-40 ... 150 °C

Process pressure

-1 ... 64 bar

View more about Point level detection for bilge and leakage monitoring on main site