Level measurement and point level detection at the belt transfer point

Category: Cement Industry

Specifications

Details

Conveyor belt transfer station

Level measurement and point level detection at the belt transfer point

|

|

Process data

Measuring task

Level measurement and point level detection

Measuring point

Silo

Measuring range up to

5 m

Medium

Stones, gravel and sand

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Extremely noisy and dusty environment, abrasion

Application

The transport of coarse and fine bulk solids within a stone processing facility takes place in most cases via conveyor belts. To achieve an even throughput and compensate for volume fluctuations during transport, belt transfer points are integrated in the conveyor line. The incoming bulk material is briefly stored in a buffer silo to prevent belt overfilling. This is the point where the level and the point level must be monitored.

Your benefit

Reliable

Reliable monitoring of silo filling

Cost effective

Optimal utilization of conveyor belt capacity

User friendly

Maintenance-free operation

Recommended products

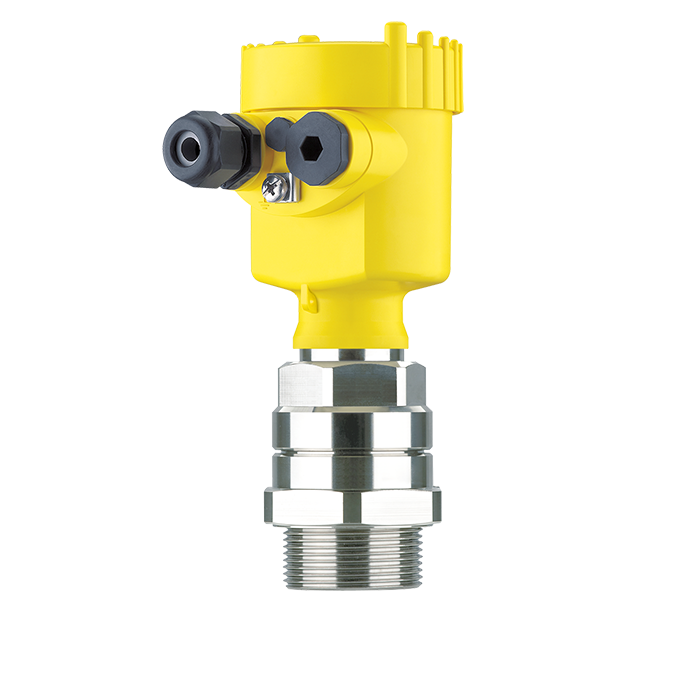

VEGAPULS 69

Non-contact level measurement with radar at the belt transfer station

- Highly reliable even in dusty environments

- Maintenance-free non-contact measurement

- Maximum operational reliability due to noise insensitivity

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

VEGAMIP 61

Microwave barrier for level detection at the belt transfer point

- High measurement certainty even with soiling and deposits

- Long service life ensured by robust sensor

- Maintenance-free operation with non-contact measuring principle

Measuring range - Distance

100 m

Process temperature

-40 ... 80 °C

Process pressure

-1 ... 4 bar

View more about Level measurement and point level detection at the belt transfer point on main site