Details

Evaporator in a distillation column

Process data

Medium

Benzol

Vessel

Evaporator

Process temperature

+350°C

Process pressure

20 bar

Process conditions

Extreme temperatures and high pressures, fluctuating density and dielectric values

Application

In a petrochemical research facility, an evaporator (reboiler) heats the liquid from the bottom of a distillation column together with different additives, so-called catalysts, and splits it into its constituent parts. The temperature in this vessel is about 350° C. The different types of benzol released are then extracted in the fractionation process. The level in the evaporator must be continuously monitored and kept constant during the process. In addition, a point level measuring system is needed to reliably detect when the maximum level is reached, regardless of the mixing ratio of the raw materials. The different catalysts cause large fluctuations in the density and dielectric constant of the measured medium. These variations and the extreme thermal process conditions place particularly high demands on the measurement technology used.

Recommended products

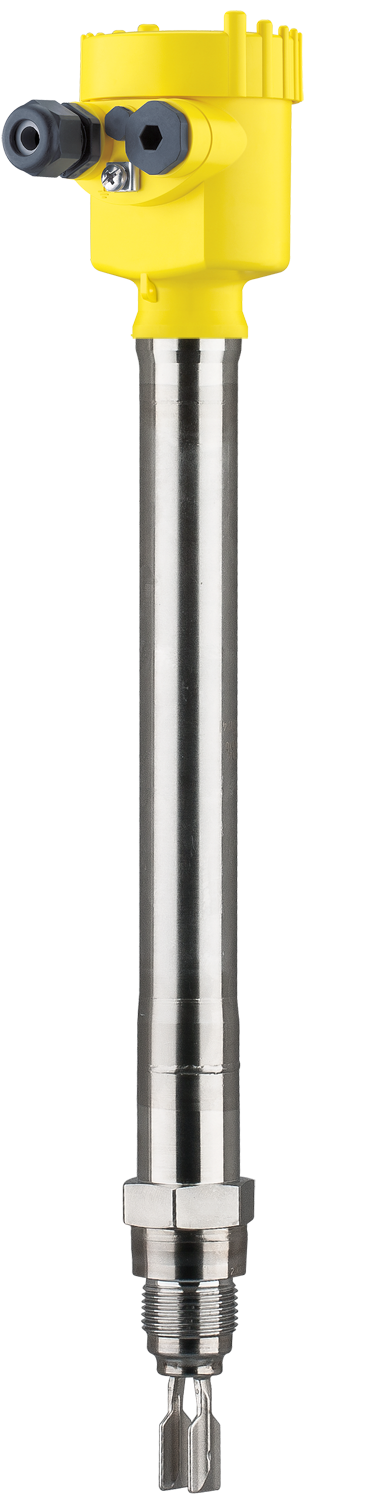

VEGASWING 66

The high temperatures and changing conditions in the evaporator require a robust and reliable measurement technology.

The vibrating level switch VEGASWING 66 is ideal for point level measurement in liquids with extreme temperatures up to +450° C and pressures up to +160 bar.

VEGASWING 66 detects the maximum permissible level of the crude oil in the distillation column and reliably prevents overfilling of the container.

The vibrating level switch VEGASWING 66 is ideal for point level measurement in liquids with extreme temperatures up to +450° C and pressures up to +160 bar.

VEGASWING 66 detects the maximum permissible level of the crude oil in the distillation column and reliably prevents overfilling of the container.

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

Version

Compact version

with gas-tight leadthrough

with tube extension

VEGAFLEX 86

The solution

The TDR level sensor VEGAFLEX 86, which is also ideal for use in hot media, measures the actual level in the evaporator. With its operating range of -196° to +450° C and 400 bar, VEGAFLEX 86 is quite suitable for extreme applications. The applied TDR sensor is also SIL2 qualified (IEC 61508) and has all required approvals for use in hazardous areas.

The dependable level control system and fail-safe overfill protection device are installed in the evaporator (reboiler), which is located at the bottom of the column in the petrochemical research facility. Together, they ensure constant recirculation of product and thus effective operation of the entire distillation column.

User benefits

- Robust, long-lived sensors with high temperature resistance

- Universally applicable point level switch not influenced by changing product properties

- Efficient, reliable operation of the distillation column through precise, reliable measured values

- Extensive diagnostic functions and SIL qualification increase plant safety

Measuring range - Distance

75 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 400 bar

View more about Evaporator in a distillation column on main site